Containerized Water & Wastewater Treatment System

1. Product Overview

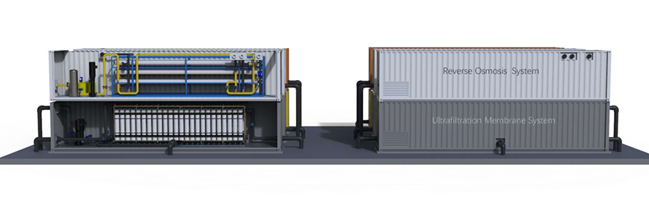

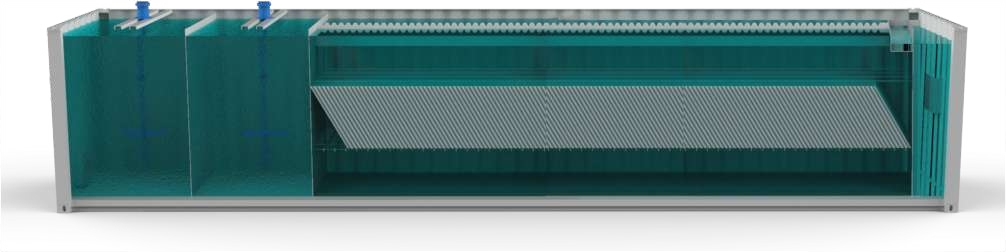

Pojiali introduces a fully modular Containerized Water & Wastewater Treatment System, built upon a complete membrane technology portfolio including MF, UF, NF, and RO. All essential treatment functions are integrated into a single ISO-standard container, forming a portable, rapidly deployable, and highly scalable water treatment solution.

Each containerized unit is fully prefabricated, piped, wired, and tested in the factory. Once delivered to the site, it can be commissioned within a few weeks.

Ideal applications include:

- Industrial process water & water reuse

- Potable water supply (surface water, groundwater, brackish water, seawater)

- Agricultural and aquaculture water supply & irrigation

This modular system encapsulates complex water treatment processes within a compact structure, eliminating the need for heavy civil works and long construction timelines.

2. Why Pojiali – Our Membrane Technology Advantage

Pojiali provides a complete membrane technology ecosystem, including:

- MF / UF / NF / RO membrane treatment capabilities

- Three membrane module formats: hollow fiber, spiral-wound, and curtain-type

- Optimized designs for high-turbidity surface water, industrial water, and drinking water

With deep expertise across diverse water qualities, Pojiali ensures membrane solutions that match real-world treatment challenges.

3. Three-Partner Collaboration Delivering the Best Solution in Taiwan

Pojiali (Taiwan)

Leads core membrane technology, market adaptation, regulatory compliance, and local after-sales service.

Fanshu Environmental (Shanghai)

Leads modular water treatment system design and product engineering.

CIMC Environmental (Guangdong)

Provides world-class ISO container manufacturing with standardized quality and reliable mass-production capability.

This tri-party collaboration enables solutions that are technologically advanced, rapidly deployable, cost-optimized, and consistently high in quality.

4. Key Advantages of the Modular Containerized System

1.) Rapid Deployment: Delivered in 3–6 Months

Factory-built modules minimize on-site complexity.

2.) Simplified Installation: Commissioning Completed in Weeks

On-site work is reduced to piping, electrical connection, and startup.

3.) Compact Footprint: Up to 67% Land Area Reduction

Ideal for space-constrained industrial and rural sites.

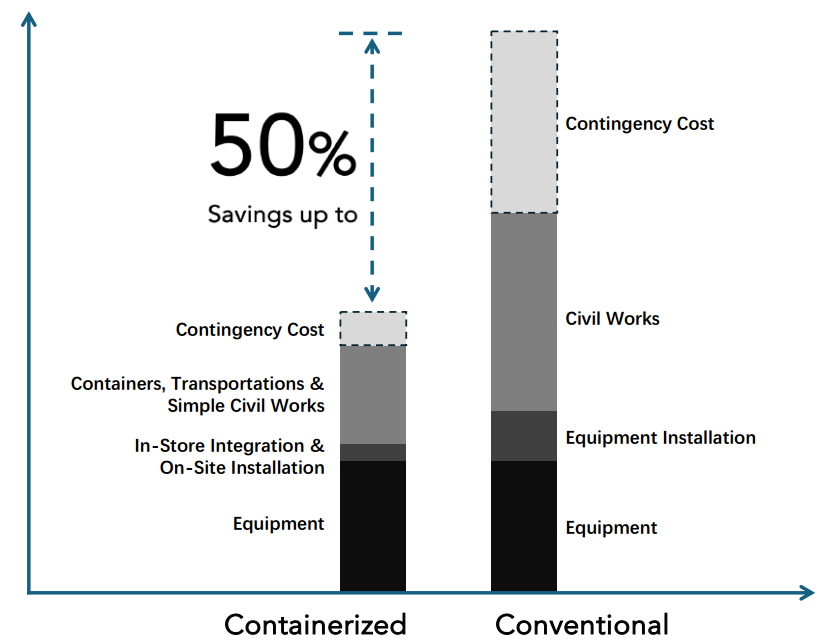

4.) Up to 50% Reduction in Project Investment

Containerized systems significantly reduce uncertainties, civil work costs, and contingency budgets.

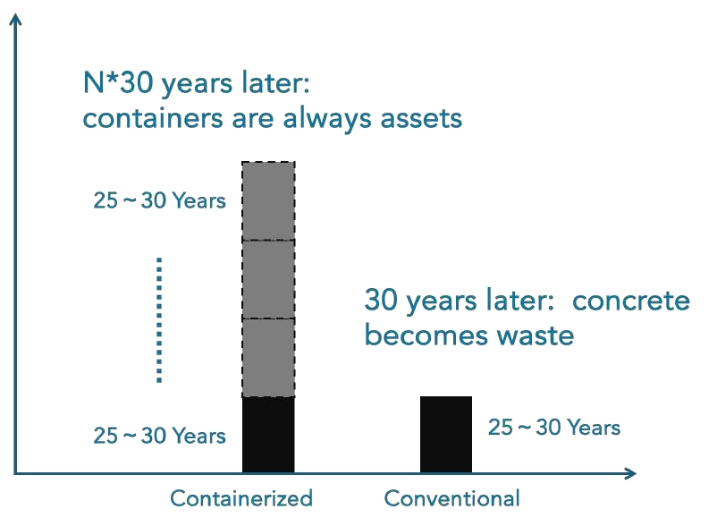

5.) Service Life Comparable to Concrete (~30 Years), but Redeployable

Unlike concrete structures that become demolition waste at end of life, container modules can be repurposed, relocated, or recycled as steel.

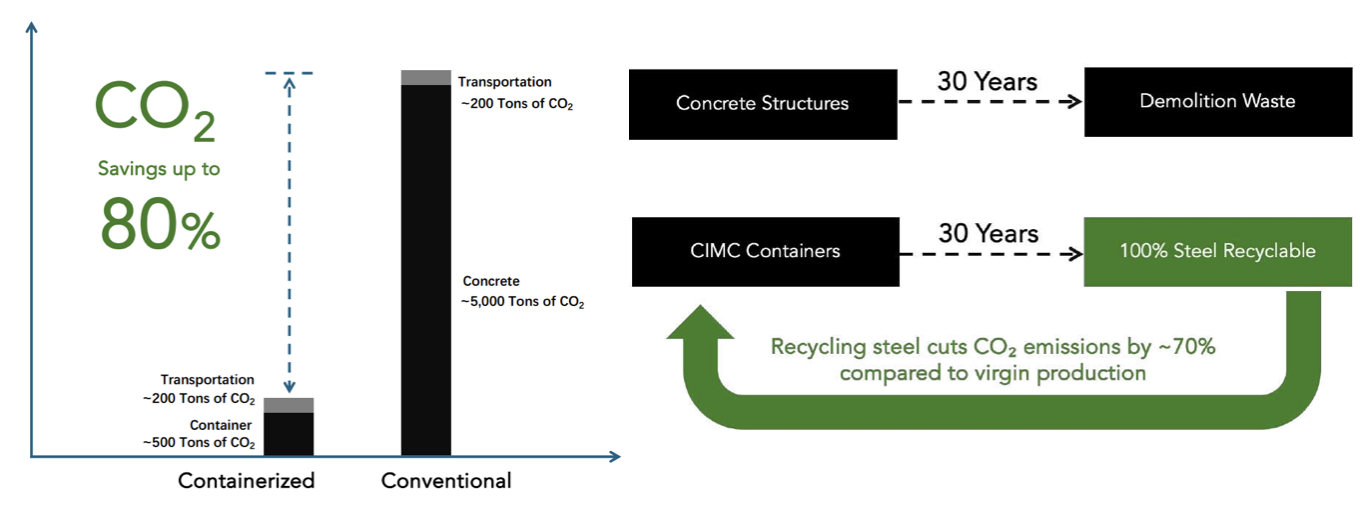

6.) Over 80% Reduction in Construction-Stage Carbon Emissions

Factory fabrication and rapid assembly dramatically reduce heavy machinery use and site emissions—supporting true circular economy principles.

5. Use Cases

✔️ Industrial Water Supply

- UF / RO for process water

- Advanced treatment for cooling water systems

- Industrial wastewater treatment (MBR + advanced reuse treatment)

✔️ Potable Water Supply

- Surface water (high turbidity → pre-treatment + UF)

- Groundwater (iron, manganese, hardness → UF + RO)

- Brackish water & seawater desalination (RO)

✔️ Agricultural & Aquaculture Water

- Irrigation water (UF for turbidity reduction)

- Aquaculture water (low turbidity, low pathogen risk via UF + disinfection)

- Mobile water supply for remote farms, fishery sites, and islands

6. Treatment Flow Processes

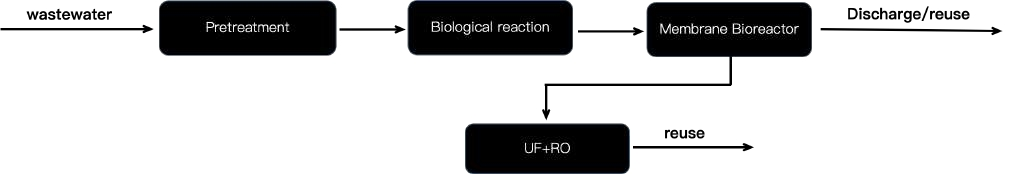

(A) Wastewater Treatment Flow (AAIWTP)

- Pre-treatment: screening → grit removal → equalization (EQ)

- Biological treatment: A2/O or AO

- MBR: UF membrane for solid–liquid separation

- Advanced treatment: UF / RO

- Final water: compliant discharge or industrial reuse

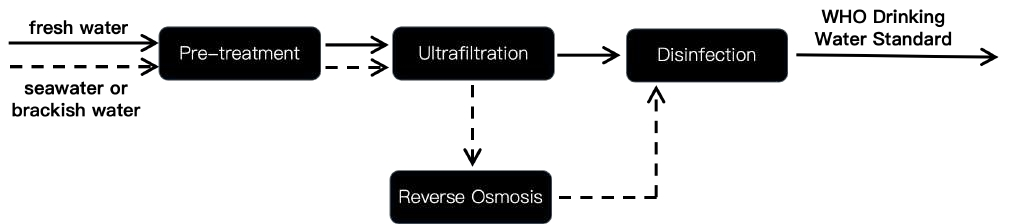

(B) Drinking Water Treatment Flow

- Pre-treatment (coagulation, flocculation, filtration)

- UF ultrafiltration (turbidity and microorganism removal)

- RO reverse osmosis (depending on raw water TDS)

- Disinfection (automatic residual chlorine control)

- Safe drinking water output

7. Modular System Models

- Standard 40 ft High-Cube container (12.19 × 2.44 × 2.90 m)

- Treatment capacity from 100 m³/day to 50,000 m³/day

- Optional modules include DAF, oil removal, advanced polishing, sludge dewatering, etc.

Flexible configuration allows scaling and customization based on raw water quality and desired effluent standards.

8. Why Choose Pojiali?

- Taiwan's only company with full in-house membrane technology development

- Deep understanding of Taiwan's water characteristics (turbid rivers, iron-manganese groundwater, coastal environments)

- Full compliance support for Water Pollution Control Act and Drinking Water Quality Standards

- One-stop solution: system design → manufacturing → site integration → long-term maintenance

Pojiali delivers reliable membrane technologies and turnkey water solutions tailored for Taiwan's industrial, municipal, agricultural, and rural needs.